How do I determine bolt grades?

Being able to determine the grade of bolts you purchase can be the difference between a solid, durable joining of two materials, or the failure of that bolt.

Below we will help you to first identify the difference in bolt grades on visual inspection.

After this article, you'll be able to walk in to your local hardware store, pick up a bolt (as long as it is one of these common types), and be able to tell what type it is, and the basic working loads you can expect from each bolt.

How to Visually Determine Bolt Grades

Bolt grades are easy to determine and important to recognize for the right application. This is a list and description of the most common bolt grades.

Grade 2 Bolts

Grade 2 bolts are the most common grade of bolts and are also the least expensive. Grade 2 bolts are found mostly in household fasteners like carriage bolts, and machine screws. The usually have no head marking, but may sometimes contain manufacturer markings.

Grade 5 Bolts

Grade 5 bolts are commonly found in many automotive applications that call for a hardened bolt but not as brittle as fully hardened. Grade 5 bolts are case hardened, meaning the bolt has been heated enough to hardened the outside of the bolt but not enough to harden the inside portion. Grade 5 bolts are identified by 3 evenly spaced radial lines on the head.

Intense amount of weight or pressure

Grade 8 Bolts

Grade 8 bolts are common in heavy manufacturing like large trucks and tractors. They are fully heat treated all the way through which create a bolt that is very hard but somewhat brittle. Because of their hardness, grade 8 bolts are more likely to snap off than bend under extreme loads. Grade 8 bolts are identifiable by 6 evenly spaced radial lines on the head.

Understanding what Bolts you Need

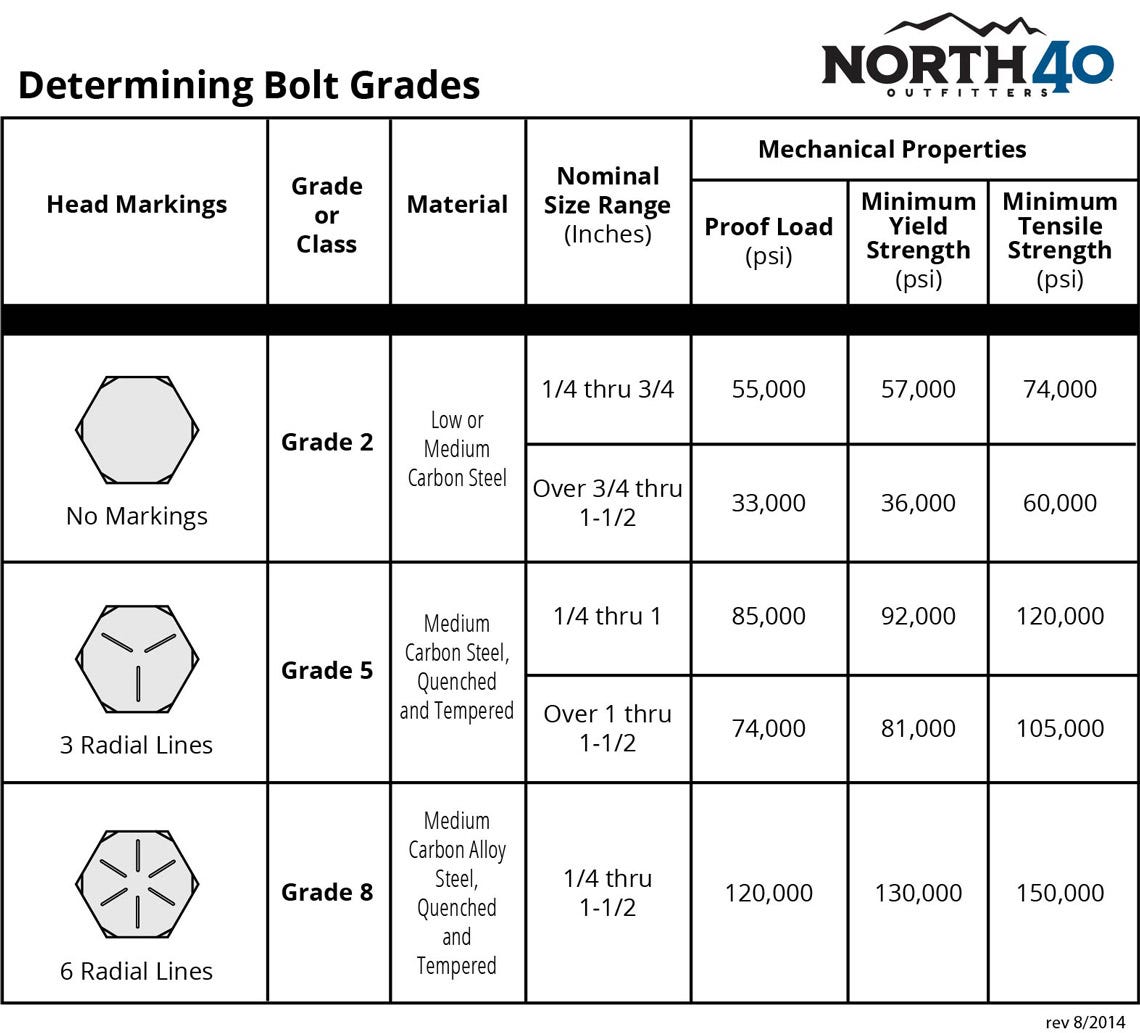

The reference chart below can help determine bolt grades and their mechanical properties. To understand this information, first you have to realize what each of these terms mean.

When considering the Proof Load, this is the amount of weight the bolt itself can support. Grade 2 bolts can support between 33,000 and 55,000, and so on. So if the join you are considering will be below the minimum yield strength, you should be good to go.

With the minimum yield strength--this is the amount of weight it will take for the bolt itself to show signs of physical deformity, bending, stretching or cracking.

Minimum tensile strength versus minimum yield strength in a bolt-- what's the difference?

Well, where "yield strength" is where the bolt starts to "give," or deform plastically, the "tensile strength" of a bolt, or bolt grade, is when that bolt will actually break.

Look below--can you tell which bolt is right for you?

Have questions about which bolt grade is right for you? Use the form below to ask your question directly, or reach out to us on Facebook right here.